PEV (Persuasive Electric Vehicle) is an autonomous bike sharing system. It's a research project at MIT Media Lab which I'm part of. It aims to solve urban mobility challenges with a healthy, convenient, sustainable alternative to cars.

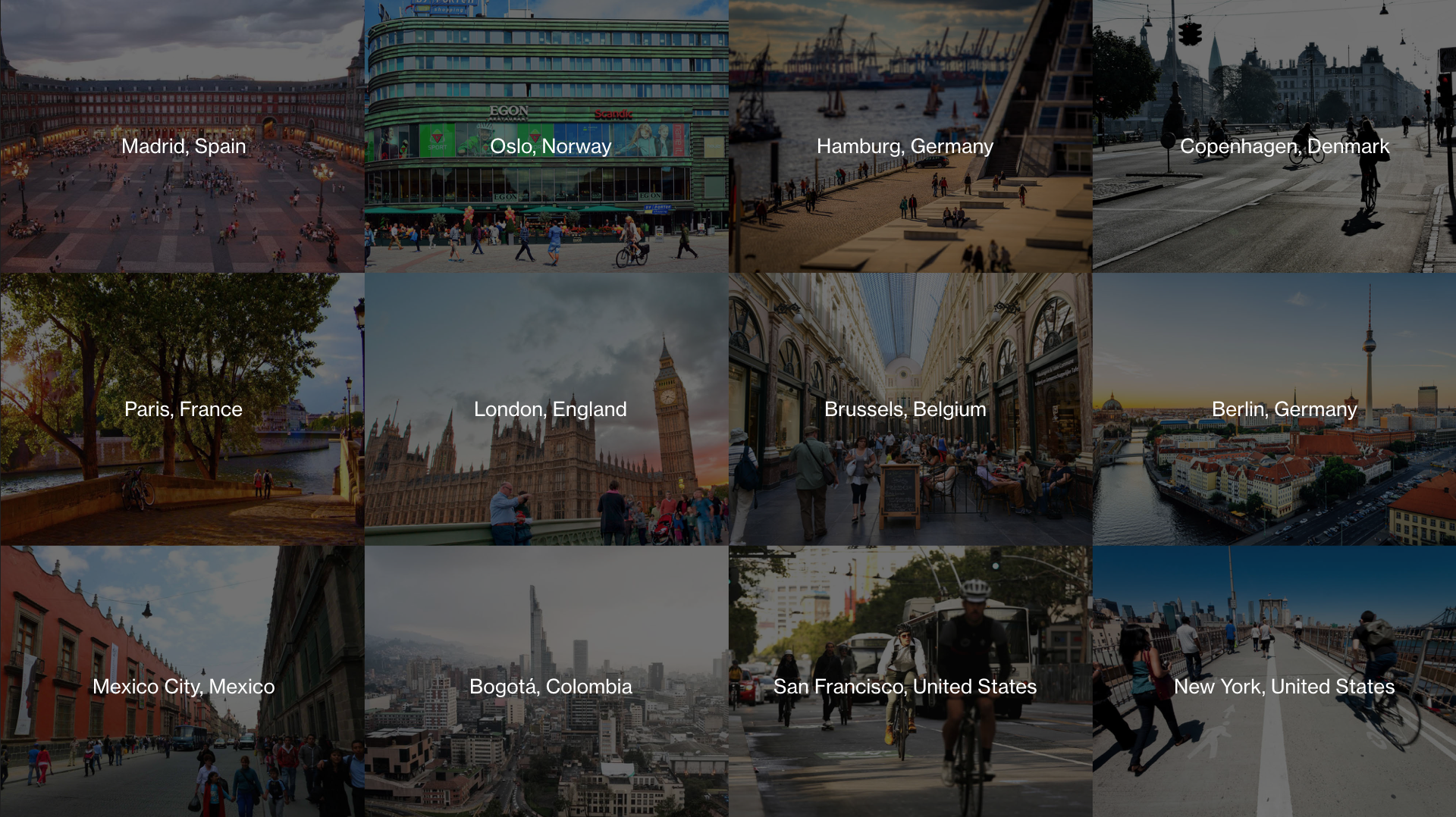

The PEV is a low-cost, agile, shared-use autonomous bike that can be either an electrically assisted tricycle for passenger commuting or an autonomous carrier for package delivery.

The PEV uses standard bicycle components and is lightweight yet robust. Its sensors are easy to reconfigure and it has a 250W mid-drive electric motor and 10Ah battery pack that provides 25 miles of travel per charge and a top

speed of 20 miles per hour. The PEV can be autonomous, operated by the rider, or provide the rider with an electric assist. PEV's operate in bike lanes, avoiding the congestion and adding incentives to make more bikeable cities.

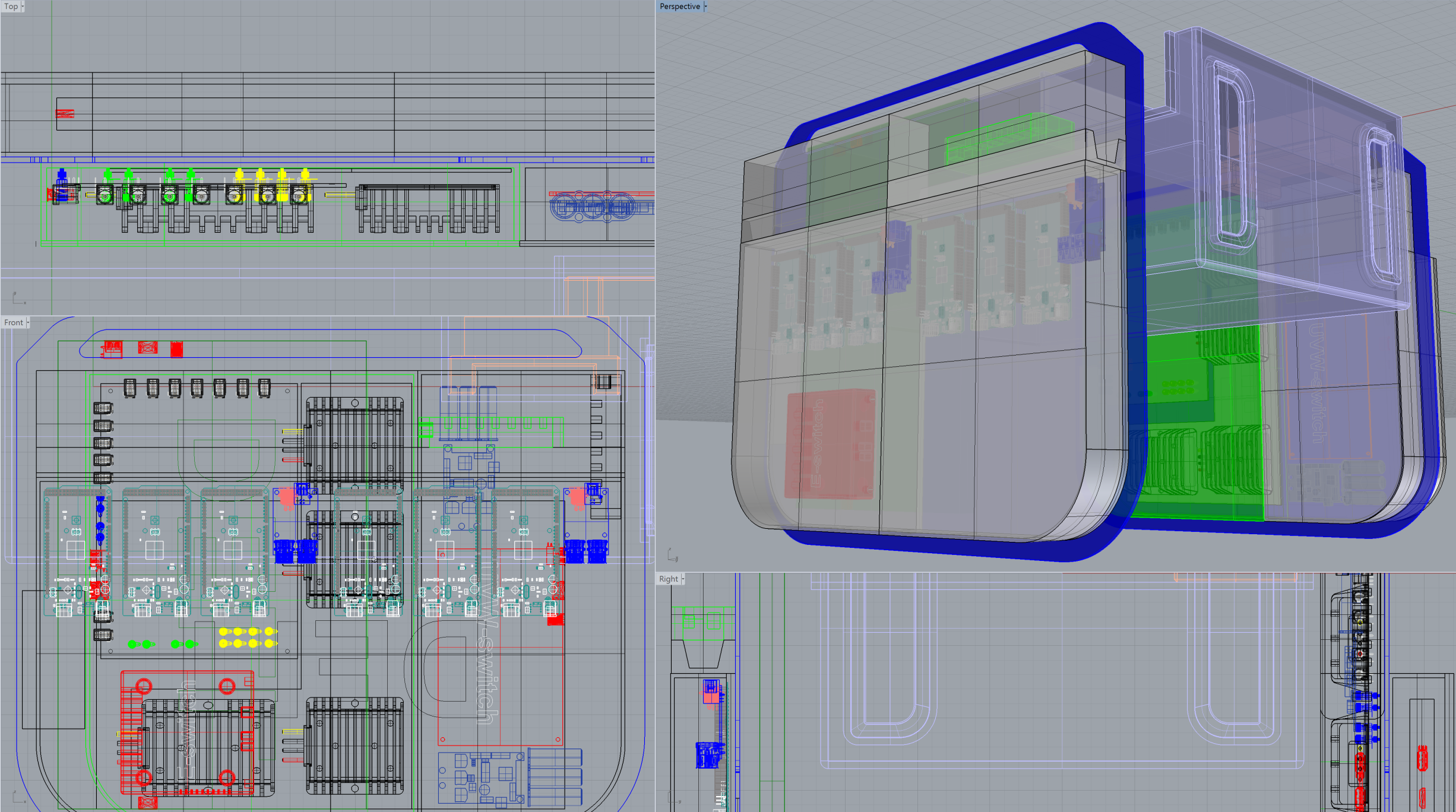

I work as a Product Design Engineer in this project. I design mechanical system, human-machine interface (HMI), and hardware system layout.

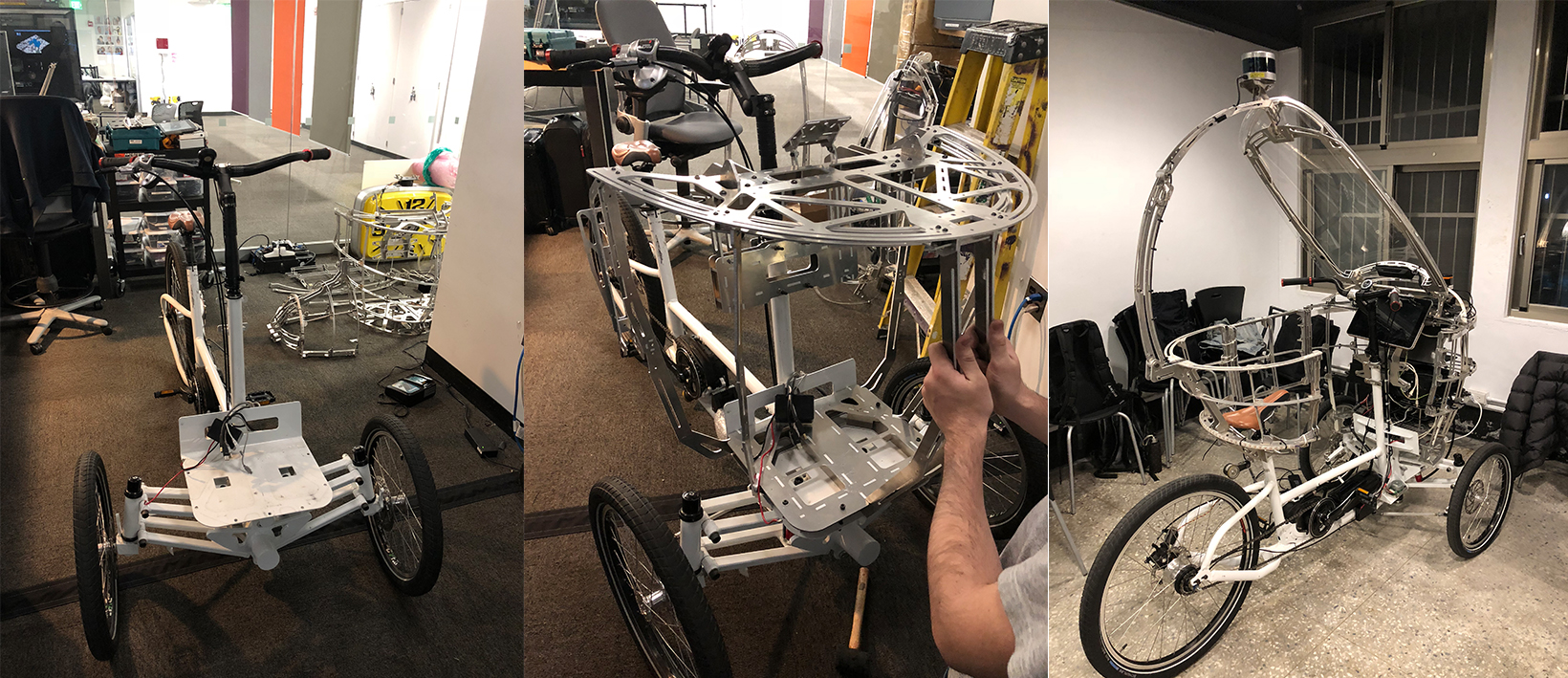

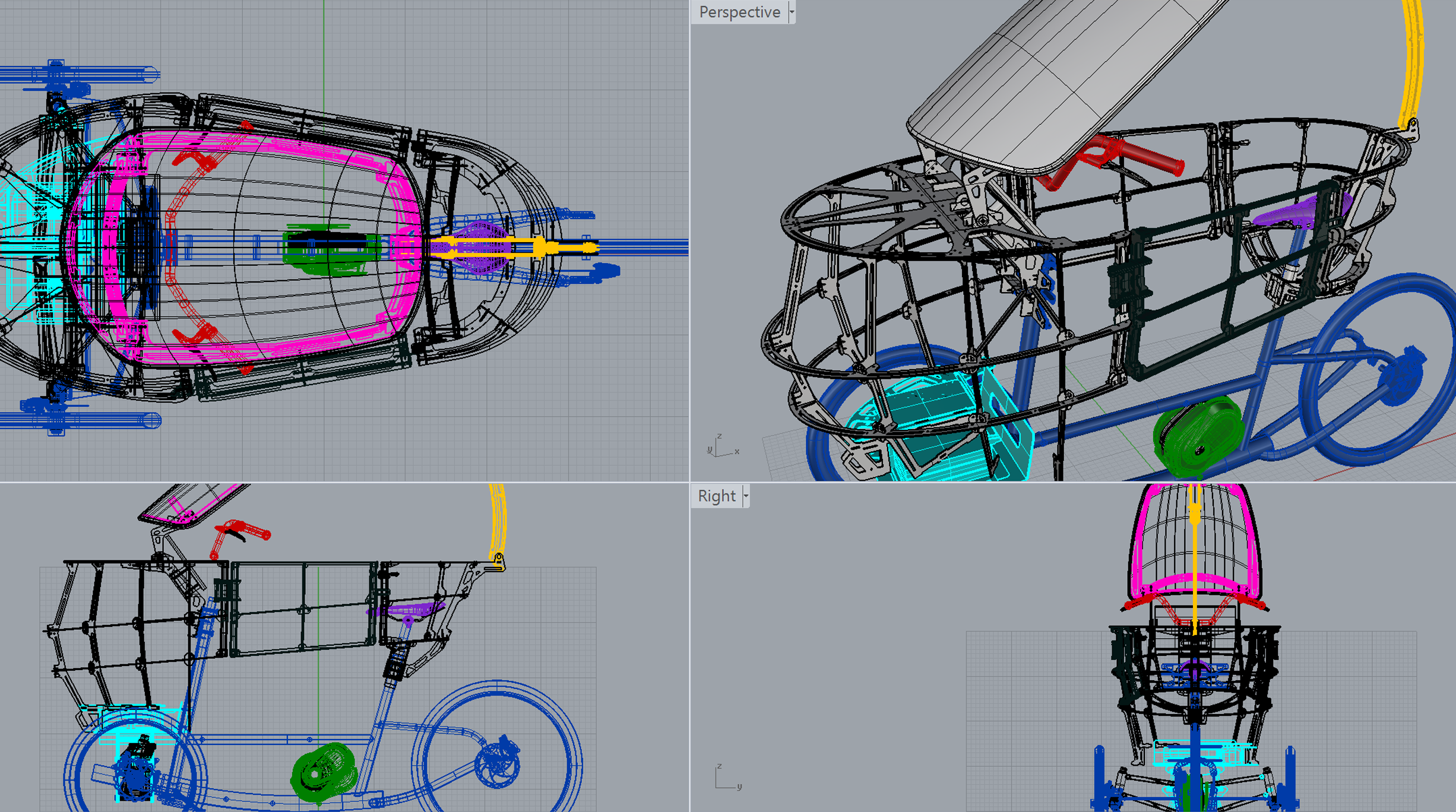

I built three 1:1 scale prototypes and fabricated them at the MIT Media Lab's machine shop.

Collaborate with engineers, program managers, research scientist, and sponsor company to build commercialized version of the vehicle.

Mechanical system design (3D modeling), prototyping, machining, fabrication.

Rhinoceros, Laser Cut, Water jet, 3D printing, milling, electrical system wiring and integration, hardware syste layout.

Michael Lin, Phil Tinn, Justin Zhang, Yago Lizarribar, Jason Wang, Vincy Hsiao, Kai Chang, Luke Jiang, Bill Lin, Danny Chou.

Learn more from the Media Lab project website.

Design a lightweigh autonomous vehicle that is agile and low cost?

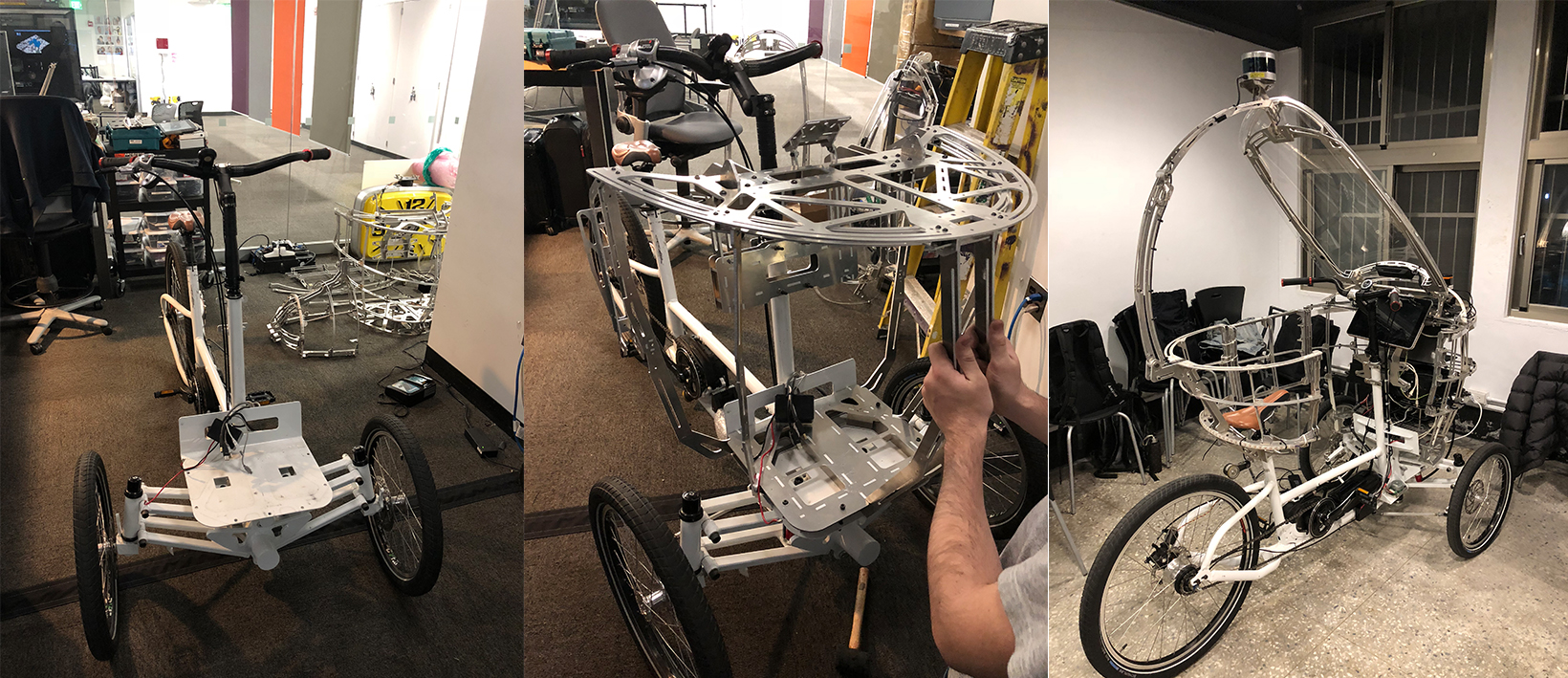

Different studies have shown that there will be less and less private owned cars in the city in the next 10-15 years. There are cities even started to ban cars from entering the city center. The world is looking for other efficient alternatives for mobility platforms within the city.

Research from MIT Media Lab presents PEV (led by Michael Lin), a low-cost, agile, shared-use autonomous bike that can be either an electrically assisted tricycle for passenger commuting or an autonomous carrier for package delivery, is a great example. How should we design the system to complete the vision?

Learn from shared bikes

The PEV uses standard bicycle components and is lightweight yet robust. Its sensors are easy to reconfigure and it has a 250W mid-drive electric motor and 10Ah battery pack that provides 25 miles of travel per charge and a top speed of 20 miles per hour.

Aluminum made prototype

In order to rapidly test different design, we chose to use aluminum to build PEV's prototype. The aluminum sheets that we use are multipurpose 6061, it is lightweight yet robust while having the malleability for us to cut, bend or reassemble.

Bike linkage study, mid-drive motor study, steering motor study.

2D CAD file studying, 3D modeling, mechanical system design, hardware layout design.

Fabrication: Laser cut, water jet, CNC, 3D printing, hardware assemble, BOM.

Parts assemble, sensors testing, collaborate with engineering teams to test drive the vehicle.

The prototype(s) were tested in the United States, Taiwan, and Japan.

The project is currently being commercialized and produced by our sponsor company Denso Corporation. Our team is working with Denso and fine-tuning the new PEV. The new version will be released soon!. I learned the importance of cable management in this project. No matter it's a small product or a gigantic vehicle, a detail-oriented electrical/mechanical system as well as wiring are extremely crucial while designing the product. I also realized the importance of making the system modularized.

Currently, we have 3 PEVs placed in Cambridge, Taiwan and Andorra respectively, and we are planning to build more for commercialized version. In order to efficiently managed all vehicles, I need to modularize the system as it would be easier for developers to make progress in the future. All these functions will be added in the latest commercialized version of PEV, so please stay tuned!